Your Lighting Solution Manufacture

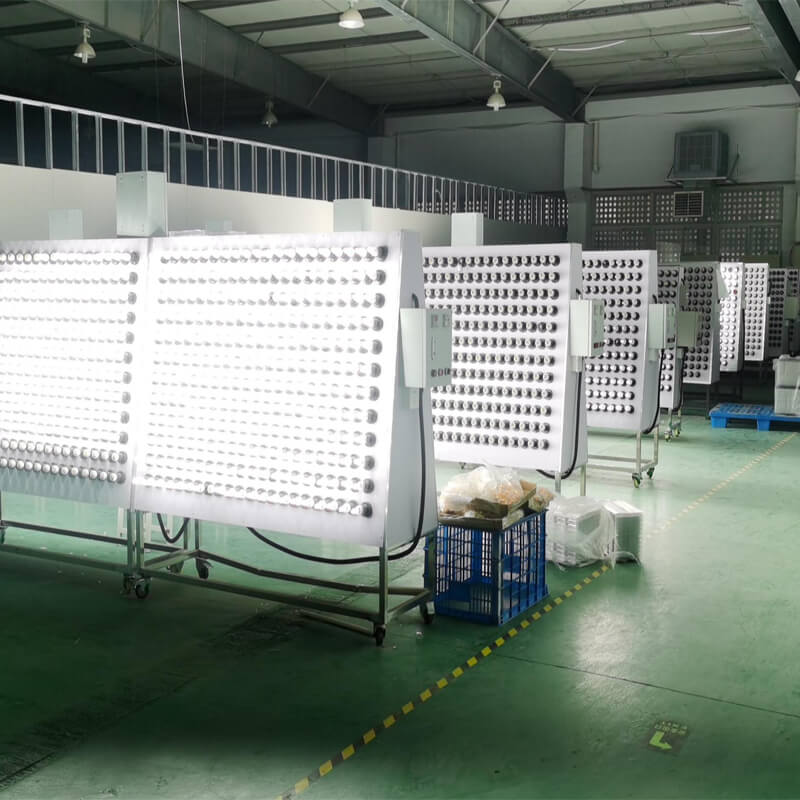

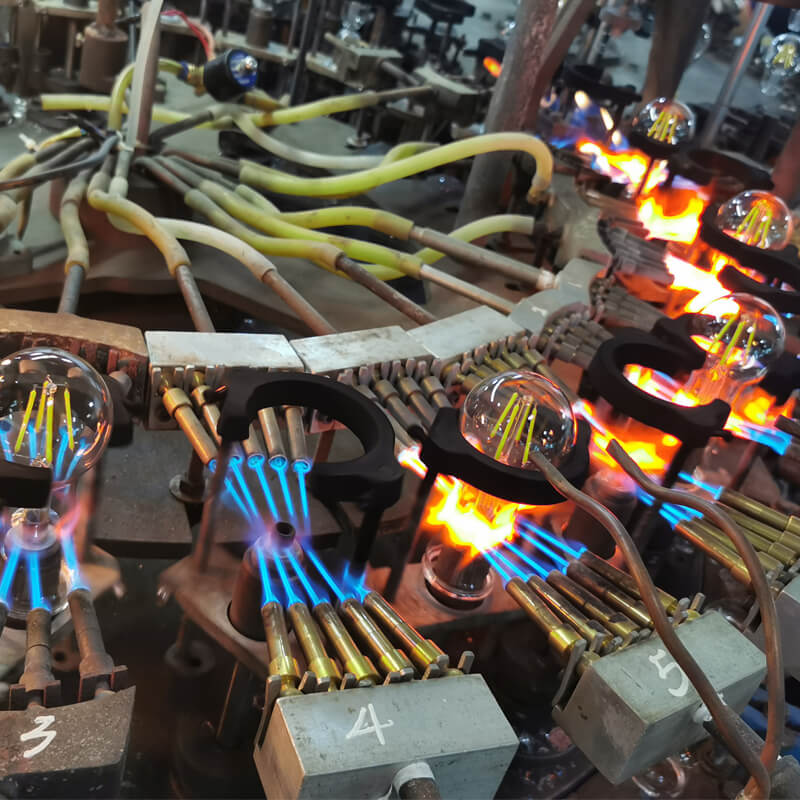

Huiyee Lighting es un fabricante de iluminación profesional en China con más de 10 años de experiencia en la industria. Aquí, puede conseguir la iluminación decorativa adecuada con confianza.

Ofrecemos una amplia gama de lámparas colgantes., bombillas LED, lámparas de pared, portalámparas, y bases, todo diseñado para cumplir con los requisitos de su proyecto.

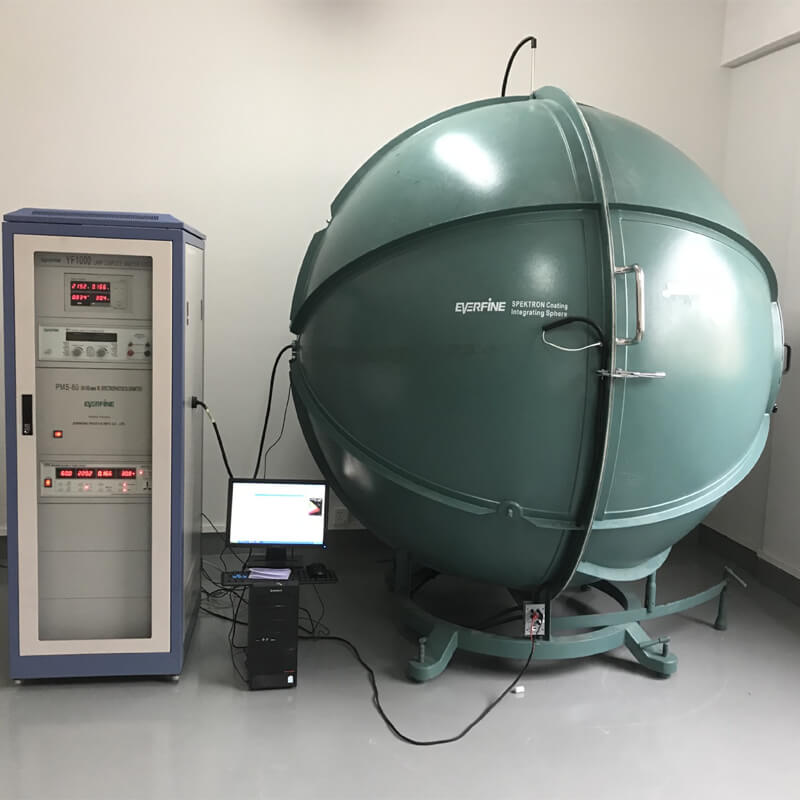

Si necesita personalización OEM u ODM, o una solución integral para decoración e iluminación del hogar., recibirá soporte flexible y confiable. La mayoría de nuestros productos son TUV., ETL, RoHS, y certificado ERP, Garantizar una calidad constante para los mercados globales..

Nuestro equipo está disponible 24/7, y puede esperar una respuesta a sus consultas dentro de 2 horas.

English

English العربية

العربية Français

Français Deutsch

Deutsch Italiano

Italiano Polski

Polski Português

Português Русский

Русский Español

Español Українська

Українська