Your Lighting Solution Manufacture

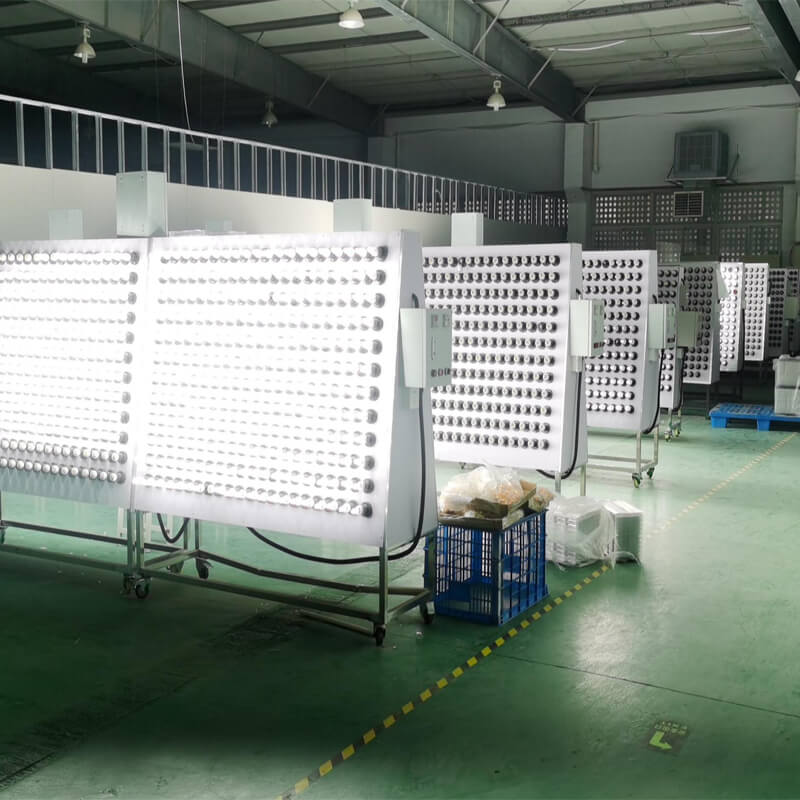

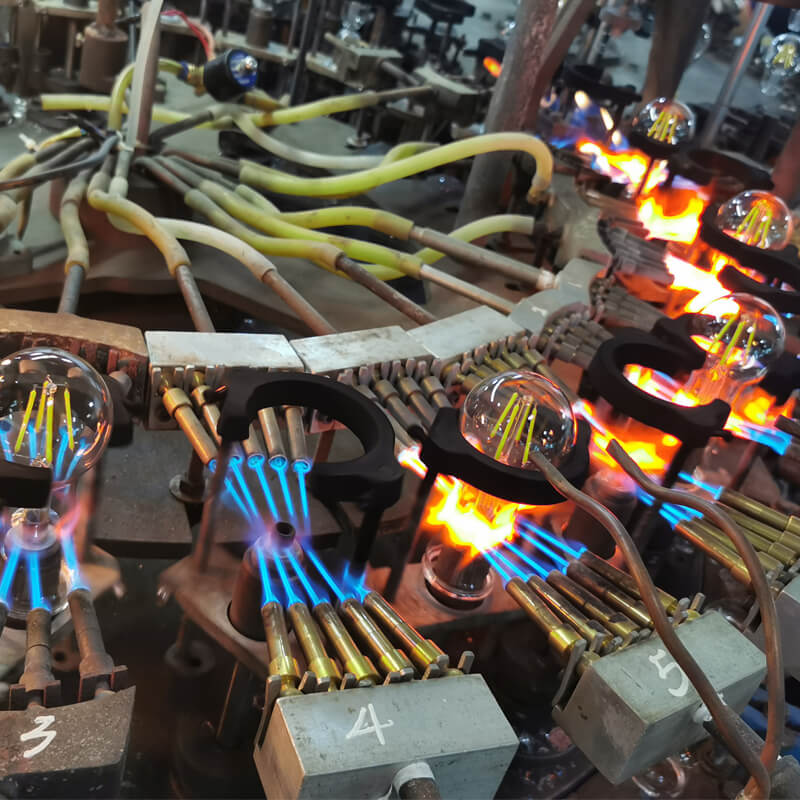

Huiyee Lighting is a professional lighting manufacturer in China with over 10 years of experience in the industry. Here, you can source the right decorative lighting with confidence.

We offer a comprehensive range of pendant lights, LED bulbs, wall lamps, lamp holders, and bases, all designed to meet your project requirements.

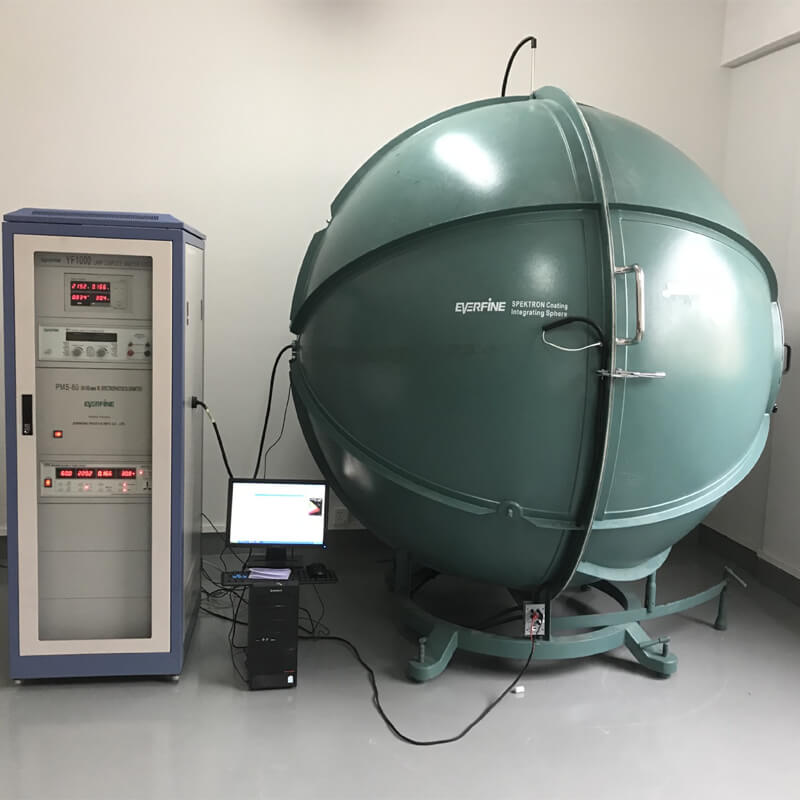

Whether you need OEM or ODM customization, or a one-stop solution for home décor and lighting, you’ll receive flexible and reliable support. Most of our products are TUV, ETL, RoHS, and ERP certified, ensuring consistent quality for global markets.

Our team is available 24/7, and you can expect a response to your inquiries within 2 hours.

English

English العربية

العربية Français

Français Deutsch

Deutsch Italiano

Italiano Polski

Polski Português

Português Русский

Русский Español

Español Українська

Українська